Relicomp is currently conducting a wide-ranging project which will produce an automated combination of washing machine and press. The impacts of the automation will be immense throughout the entire chain. In the future, work phases will be completed more efficiently and safely with machines performing all work tasks requiring physical exertion. Automation will also maintain our competitiveness in years to come and ensure that our delivery capacity grows with our customers.

The two-robot assembly lightens the work load without cutting jobs

The automated combination of press and washing machine will have many uses. In addition to large production series, we will be able to keep manufacturing small series and prototypes as well. The solution is a kind of hybrid in which automation and hands-on work supplement each other.

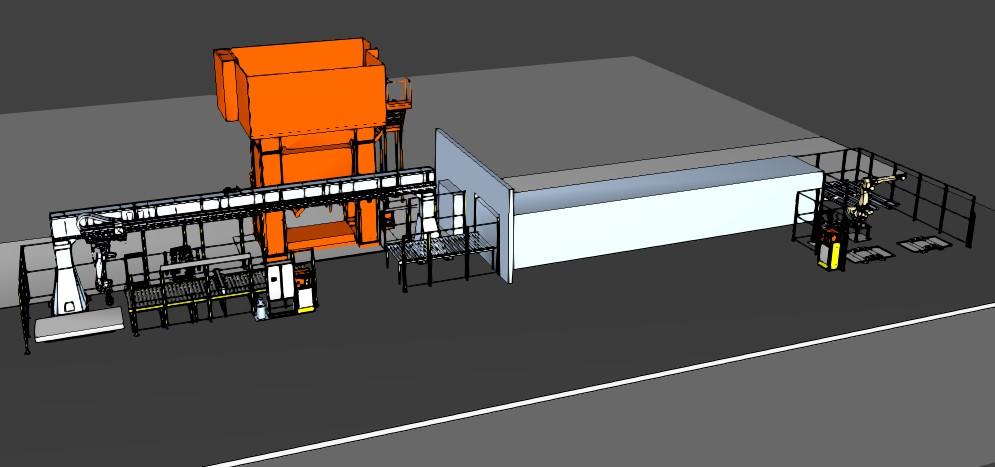

Alongside the press and washing machine, the assembly will include two robots and a lubrication device positioned first on the line. The lubrication device applies a thin oil film on the billet to enable deep drawing. After the lubrication device, the robot picks up the billet and moves it to the press, after which the robot moves the pressed billet to the washing machine. The washing machine then washes off the oil, and the other robot stacks the piece in the designated place. For these movements, the robots utilise machine vision. Previously, all work phases were performed manually. The billets were first oiled on both sides with a roller and washed by hand after pressing. Turning and moving the pieces used to present their own challenges as these, too, were done manually.

Even though the automation will eliminate many manual tasks, it does not reduce the number of employees required.

“The same people who are now working with the press will continue with the automated system. Their job is to make sure that the production chain works as intended. They mount the tools on the press and maintain them, bring the materials to the machine and move finished pieces from one station to the next. Working with the automated press and washing machine will largely involve configuring settings and monitoring quality,” says Jarkko Ketomäki, who supervises cutting and shaping at Relicomp.

The system was planned for a long time with due consideration to the physical strain of workers

The factors behind the project were quality assurance and maintaining a high level of delivery reliability. That said, the most important spark for the automation process was improving employee safety and working conditions.

“The first step of the entire project was taken based on a development suggestion from our staff. We had already gotten the press earlier and were using it a lot. The pieces it was used to process were heavy and hard to handle. Working with the press was physically taxing, so development was needed. Automation makes the working conditions safer and more comfortable for the workers as it significantly reduces the physical strain of the work,” Production Manager Tero Syrjälä says in summary.

The first ideas of the assembly were scribbled on paper in the autumn of 2019, after which digital modelling with our Visual Components software began. Many Relicomp team members took part in the design and contributed ideas to ensure that every possible area was covered. Once a rough design was finished, equipment suppliers were included in the close cooperation. Relicomp’s Project Manager Joona Nevala has served as something of a conductor for the project that was planned for a long time and with care. According to Joona, the project was challenging but also extremely interesting.

“None of the available assemblies meets our every requirement. The system will consist of so many different areas that a single equipment supplier cannot provide the entire package. This has made the project challenging. Many things have been further specified along the way and will continue to be down the road. Small actuators, in particular, are in a constant state of change.”

The automation will be deployed in phases

The modules of the assembly will arrive at the Relicomp factory in phases and be tested for commissioning individually. The most significant investment, i.e. the press, is already in production use. The lubrication device will arrive next, followed by the washing machine after the summer holidays. The third and final phase will take place in the autumn with the delivery of the press robot. We will get to test the operation of the entire assembly towards the end of the year. Once the equipment has been tested and fine-tuned, production development will begin to ensure that the entire process works smoothly.

The assembly will be operating at full capacity in the spring of 2022.